Bollards very often vary between countries and ports due to historical and geographical factors, making it difficult to find a bollard that suits the needs of each port terminal.

Prosertek USA, as a worldwide supplier, is designing and producing bollards of different shapes and sizes suited to most of the existing docks. The high quality and stability of our bollards also guarantee a long service life with minimal maintenance.

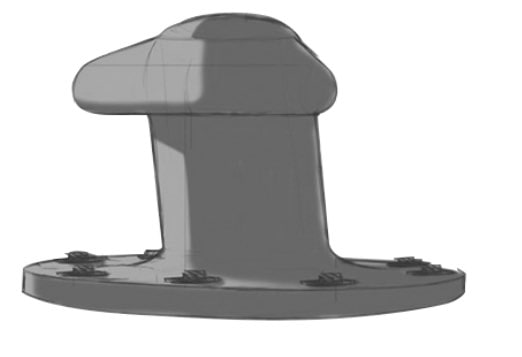

Cast steel

Cast steel Ductile cast iron

Ductile cast iron Grey cast iron

Grey cast iron