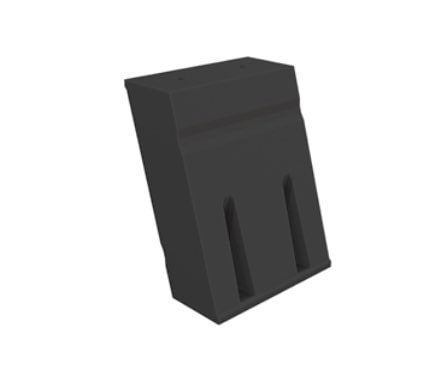

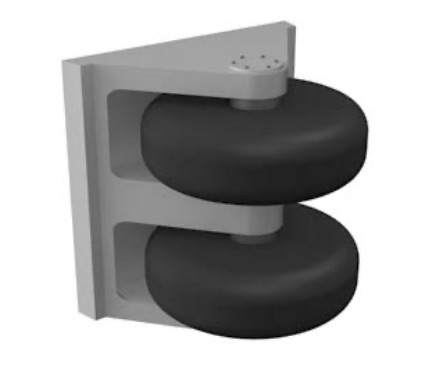

Marine fender systems are the safe interface between the berthing vessels and the berth structures. The principal function of the marine fender systems is to absorb and transform the vessel’s kinetic energy into reaction forces which can be supported by the berthing structure and vessel’s hull.

Prosertek USA is a global provider of marine fenders and has a wide variety of top-quality and solid fender to adapt to the needs of each port. We are also aware that in many cases, there is no one single solution, the reason why we are her to offer you advice based on the features of your project.